Is the micromobility business model sustainable or feasible?

E-bikes' fast adoption, popularity, and rise above electric vehicle use have helped create a

thriving micro-mobility sector. Cities have embraced sharing platforms, and operators have announced new e-bike infrastructure plans—and laws—to accommodate a staggering 240% growth rate in sales.

However, since the boom, we've begun to see cracks in the micro-mobility industry. Issues around sustainability and financial feasibility have surfaced. We are learning that the original business model only leads to short-term profitability and isn't sustainable.

There are micro-mobility potholes regarding long-term profitability and sustainability, but this no longer has to be an either or. Micromobility is undoubtedly positive, and there are ways to create a more profitable and sustainable industry for the good of the consumer – and the climate.

Urban growth on the horizon

We live on an increasingly urban planet. According to the World Bank, the world's urban population will increase from today's 4.4 billion to six billion by 2045, with nearly 70% of the planet living in cities by 2050.

Urbanisation creates enormous transportation challenges. Public transport, already struggling in many global cities, will experience even more strain. Municipalities are attempting to reduce car use, a trend that's likely to continue.

Into the space come the white knights of urban transportation: e-bikes and e-scooters. Citi Bike, owned by ride-hailing company Lyft, is the most extensive docked bike-sharing system outside East Asia. The company reported that e-bikes accounted for 32% of its rides in New York in 2021, comprising only 20% of its total fleet. CleanTechnica said that Miami e-scooter manufacturer Fluidfreeride's sales are up more than 70% over March 2021, while another manufacturer, Bird, saw sales increase 60% in March 2022. E-bike sales will reach 40 million units worldwide this year, with 300 million in circulation—a 50% increase from 2019.

So if it's a booming industry, what's the problem?

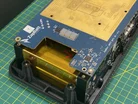

Batteries - micromobility's core

As micro-mobility continues to soar, the battery remains core to both the advancements and challenges in the sector.

An issue is that the leading e-bike and e-scooter manufacturers use the same type—and often even the same brand—of batteries, leaving these companies constrained by what the battery can do.

There seem to be a lot of options for a consumer looking to buy an e-bike or e-scooter. However, in reality, the choice only lies within the different cosmetic bells and whistles of the bike or scooter, with no real fundamental differences in its most essential part—the battery.

For mobility-as-a-service (MaaS) companies running businesses that rent out these means of shared transportation, much of the focus has been placed on the immediate purchase price rather than the long-term savings and conveniences.

The industry must improve conveniences, sustainability, and safety to advance.

Conveniences

Currently, e-bike riders have to wait about 6-8 hours to charge their bikes fully. If the battery dies, there is no quick charging option that can quickly get them on their way again without damaging the battery. The same is true for ride-sharing programs. When batteries die, e-bikes and scooters must be picked up and transported (most likely by gas-guzzling ICE vehicles) to and from charging sites. Worse yet, the batteries are swapped out, causing a sustainability nightmare.

Sustainability

Typically, e-bike batteries last 2-4 years, depending on how people ride the bikes. While it seems that riding an e-bike is green, the fact is that every few years, these batteries are thrown away. Also, let's not forget about the carbon footprint of making these batteries.

Safety

More than 100 e-bikes have caught on fire in New York this year alone. This was caused by the influx of e-bike delivery drivers, many of whom use bikes with cheap batteries that overheat and are damaged from frequent use. Many people are unaware of the fire dangers of lithium-ion batteries within today's micro-mobility applications. As e-bike popularity continues to soar, so will related fires unless new battery technologies are implemented.

The cosmetic features and short-term thinking in the micro-mobility space need to be removed and replaced by a change in the battery type. Only then can significant change in the industry—affecting manufacturers, MaaS companies, retailers, consumers, and cities—occur.

Thinking about profitability in the long term

The battery is the gatekeeper to profitability in MaaS. Nearly every aspect of the business model, including labor, up-time, warehousing, capital, and ridership, is built around battery performance. And historically, deciding which battery to choose has come down to two metrics: cost and range.

To tackle this, companies need to flip how they assess batteries. Moving on from cost and range, now is the time for companies to understand the entire lifetime expense of a battery. The bottom line is affected by battery sustainability, safety, and charging times.

Charging e-bikes and e-scooters for ride-share programmes is inefficient, expensive, and time-consuming. It involves removing them from the streets and loading them onto trucks for transport to offsite warehouses. The battery recharging process can create an entire day of un-use, reducing operators' revenue opportunities.

This is a particularly unwieldy and unsustainable process in large cities, where charging and maintenance must occur at scale. For example, according to Laura Fox, General Manager of Citi Bike, regular bikes can be used 10 to 15 times per day in New York, with e-bikes not far behind. That means a lot of costly – and unreliable – maintenance, as charging and operations are estimated to eat up 60% of costs.

The answer isn't swapping batteries

One way operators have attempted to improve efficiencies is through swappable batteries. Rather than collecting e-bikes and e-scooters and transporting them to a central warehouse for charging, crews are sent out to swap batteries on-site. This cuts down on congestion, keeps e-bikes and e-scooters in circulation, and prevents lost revenue. Sounds good, right?

While this process saves on operational costs, it wastes batteries. Often, batteries that still have 30-40% of life left are swapped for 'full' ones, which, due to degradation, can be as low as 80% of their original capacity. This swapping significantly reduces the battery's lifespan, with e-bike batteries capping out after about 500 charging cycles.

To run the swappable system efficiently and allow additional battery charging to keep the process moving, things like e-scooters require an estimated 1.5 to 2 battery packs. A fleet of 10,000 e-scooters would need at least 15,000 batteries. This system is costly.

Currently, the industry views batteries like the computer hardware industry views printer ink cartridges. It works on a similar model: swap old toner cartridges for new ones. However, there's a key difference: up to 30% of toner cartridges get recycled. In contrast, less than 1% of Lithium-ion batteries get recycled in the US and EU.

There are also significant safety issues with swapping batteries. Battery packs are easily damaged, and the sheer volume of swapping results in exposure to the elements and regular mishandling. Damage caused by battery swapping can also increase fire risks.

The new battery tech is here

The existing micro-mobility models have room for improvement if we want to create a profitable industry.

Cheaper e-bikes and e-scooters can help, but that's not enough to dramatically drive down costs and improve efficiency. Instead, we must look at the battery to enhance efficiency and sustainability.

We've seen that swapping batteries isn't a long-term solution for costs or the environment. Ultimately, the industry needs to consider drastically cutting the volume of manufactured batteries and instead use batteries that last longer. Battery production is carbon-intensive, particularly when you add in the carbon footprint of shipping—so the fewer batteries we need to produce, the more sustainable future we create.

Further, because the battery is the cause of many operational problems and costs, finding solutions is critical for both the bottom line and the planet. Alternative battery technology and moving the industry away from cheap batteries can shift this trajectory.

Lithium-titanate for micro-mobility

Lithium-titanate chemistry was designed to move energy quickly and squashes charging times from hours to minutes, allowing operators to move the charging ops to the field. The chemistry fosters a far longer life span—up to 20 years—giving micro-mobility operators the chance to reduce the swap-and-replace cycle while also helping reduce the number of battery purchases.

LTO batteries can keep e-bikes and e-scooters on the city streets for extended periods and safely without fire risks. Not only does this generate improved revenues and reduced downtime, but it also vastly improves the rider’s experience.

Micro-mobility continues to evolve with power sources. Gas is harsh on the environment, and lithium-ion has fire risks. Now lithium-titanate is ready to ride and bring increased profits to the micro-mobility sector with vast improvements in sustainability, conveniences and safety for riders. Micro-mobility battery technologies of today will soon be referred to as a thing of the past, much like dial-up internet. Once riders and business owners get a taste of all the advantages of LTO, they won't go back.